Ethan Rowe, Christopher Thierauf. IEEE/MTS OCEANS 2025.

How can we make sure our deep-sea assets return to the surface, even under the most catastrophic failure conditions?

This post summarizes work with collaborator Ethan Rowe. I provided background knowledge, advising, and writing; he did all of the technical work, ideation, and also did writing. You can read the paper here. All correspondence should be directed towards Ethan.

A Mechanical Fuse for Deep-Sea Safety

When we send expensive AUVs deep underwater, safety is our top priority, but getting them back safely is next. That’s why we use backup abort systems: Sentry has separate dead man timers and burnwires that can be triggered by sound. Other methods include frangibolts and galvanic timers. These systems drop ballast to help the vehicle float up if something goes wrong. But they all need power, electronics, and active monitoring. What happens if the power fails?

This work was motivated by the need for a fully passive mechanical fuse for deep-sea vehicles. Instead of relying on sensors or circuits, this fuse breaks mechanically at a set pressure, releasing ballast and saving the vehicle even if power is lost. The key advantage is simplicity, which is essential for safety.

Core Idea

The design is inspired by electrical fuses. Like an electrical fuse that protects a circuit by breaking, this mechanical fuse protects the vehicle by sacrificing itself.

The ballast is held by a bolt-like part with a built-in lattice. Ethan designed this lattice to stay strong as long as the vehicle stays within its depth limit. But if the vehicle goes deeper than planned, the water pressure becomes too high, and the lattice breaks. When it breaks, the ballast falls off and the vehicle rises back to the surface.

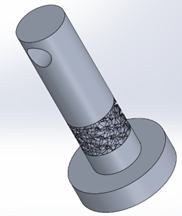

CAD and real-world design.

Designing the Fuse

To work well, the fuse must break at the right depth. The design uses a diamond lattice structure because it spreads stress evenly and breaks predictably. With modern 3D printing, we can control the lattice shape, size, and material to make it break where we want.

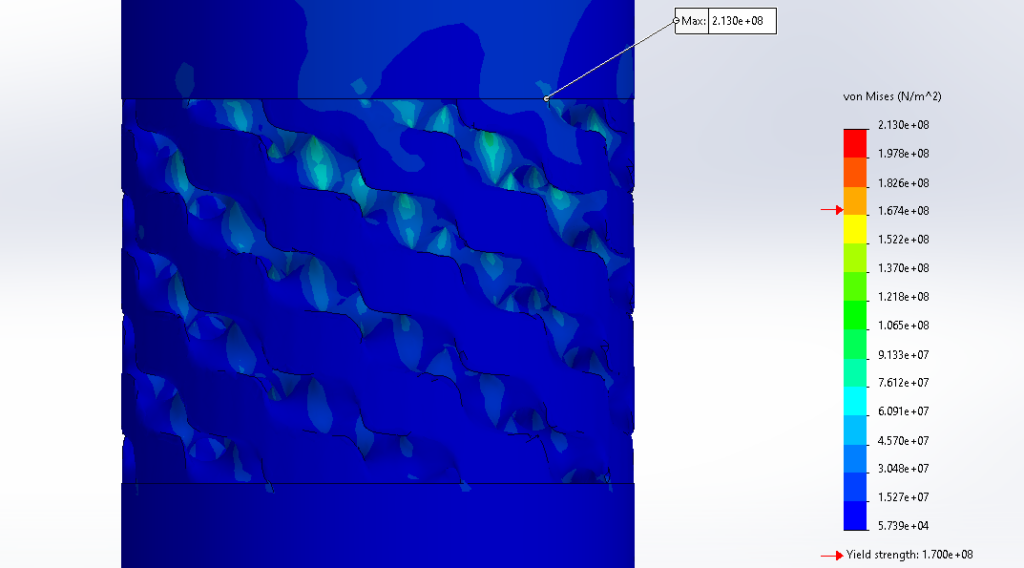

Ethan modeled the fuse using Finite Element Analysis (FEA) in SolidWorks, focusing on:

- Stress distribution across the lattice to avoid weak points.

- Deformation under hydrostatic pressure shows uniform buckling.

- Failure mode causes sudden shear when the limit is reached.

Simulations focused on about 750 feet of saltwater. We tested parameters using two materials: AlSi10Mg and 316L stainless steel. The 316L with 3 mm struts gave the best balance of strength and reliable failure.

FEA of bolt lattice section. Note that the failure is uniform and catastrophic: a single, sudden point of failure.

Results and Prototyping

The FEA simulations showed exactly the behavior we wanted:

- The lattice stayed strong under expected loads.

- Once the threshold was passed, it failed completely and suddenly.

- Stress distribution was uniform, reducing risk of partial or uneven failure.

We 3D-printed prototypes using SLA to simulate laser powder bed fusion (LPBF). These were not full-strength subsea parts but showed that the lattice design can be made. LPBF is still the planned method for final production.

Looking Forward

This project is currently in the simulation and prototype stage. The next steps include producing test parts using LPBF, utilizing CT scans to verify lattice consistency, and conducting hydrostatic tests in a pressure tank to determine failure depths. Following these, we plan to perform field tests on AUVs and potentially refine the design for scientific instruments.